|

|

|

|

HOME |

PRODUCTS |

A-SERIES |

M-SERIES |

D-SERIES |

ADAPTERS |

LABS |

ABOUT |

BLOG |

CONTACT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Series and Application Guide |

|

|

|

|

|

|

|

|

|

Series

description and comparison |

|

|

|

|

|

|

|

|

|

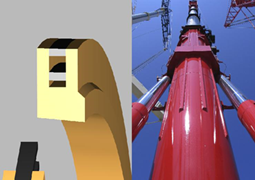

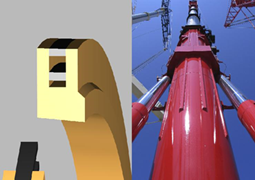

The

Hydrowype family of rod scrapers and wipers address varying degrees of

severity in conditions encountered in motion applications. Hydrowype wipers

are typically used in relatively harsh

conditions, often characterized by temperature extremes (derived either from

ambient temperatures or induced from pressure/duty-cycle), presence of

abrasives or other aggressive forms of contaminants, or factors that have

lead to the unpreventable occurrence of rod damage or abrasion. The range is

intended to provide a continuum of increasingly robust wiping solutions for

increasingly extreme conditions. Many Hydrowype wipers are constructed of

metal, either as a component of the

material itself (for example bronze-filled polymers) or more usually in a

solid, precision-machined scraping element. All Hydrowype parts are

precision-turned or ground for maximum concentricity and roundness, providing

for superior sharpness of scraping surfaces and precision relative to rod

geometry. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

a

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

The

superiority of metal as the basis of a scraping/wiping solution over

traditional polymer or elastomeric materials is field proven as well as

supported by extensive testing. Free of the vulnerabilities of aging,

embrittlement, crazing, cracking, and

compression-set, a metal wiper can be expected to substantially out-perform

and out-last a polymer wiper in harsh conditions. A correctly mated

metal-to-metal fit allows for closer contact between rod and wiper thus

avoiding “over-ride” and maximizing the potential for sustained scraping.

Metal has other beneficial attributes, such as an ability to maintain a

constant modulus of elasticity over time, making for conformity to rod

irregularities that may result from wear and damage and emerge over time and

cycles. In the presence of high pressures and temperatures that in other

materials are likely to induce hardening, crazing, embrittlement and

compression-set, metal will in fact increase in performance. |

| |

|

|

| |

|

|

| |

|

- series |

|

| |

|

|

| |

|

|

|

|

|

d

|

|

|

|

|

|

A metal

rod wiper regularly exposed to high temperatures will normalize, relieving

internal stresses and ensuring continued suppleness to aid in rod conformity.

Metal also has a sacrificial tendency, so a correctly matched softer alloy

will lubricate the rod, depositing material from the wiper body around the

high points and into the low points of nicks and burrs on the rod surface,

thus smoothing the irregularities to prolong the life of seals. |

| |

|

|

| |

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

The following are

some of the wiper variations offered within the Hydrowype product family. |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Rod

Wipers/Scrapers (A-Series, D-Series and M-Series) |

|

|

|

|

Hydrowype

rod wipers are intended to scrape clean of contaminants, the external surface

(outside diameter) of hydraulic, pneumatic, landing-gear, actuator and other

rod types. Available in a range of different profiles and pre-loads, the

geometry and manufacture of this wiper range can be adapted to fit specific

circumstances, such as low-load's to minimize breakout friction in

low-pressure applications, or high-load's to take advantage of ample

actuating power to maximize scraping potential. The common element of all

Hydrowype wipers is the precision scraping edge along with a selectable (at

time of manufacture) bore taper to permit sustained scraping throughout the

intended lifespan. |

| |

|

|

| |

|

|

| |

|

|

|

|

|

|

m

|

|

| |

|

|

| |

|

|

Bore

Wipers/Scrapers (B-Series) |

| |

|

|

Hydrowype

bore scrapers are constructed as both active and passive devices and provide

a precision scraping edge on the outside diameter for use in applications

where a bore or cylinder interior needs to be maintained free of

contaminants. Active scraping potential is achieved through the use of

"c" springs installed individually or in pairs to maintain external

pressure against the bore surface. Like rod wipers, bore wipers are available

in standard sizes as well as custom diameters and profiles, to allow for the

optimization of scraping potential in association with lifespan expectancies

and wear characteristics. |

| |

|

|

| |

|

|

| |

|

|

| |

|

- series |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Military

Specification – MS28776M2 (A-Series) Scraper Rings |

| |

|

|

The

Hydrowype A-Series wiper is the standard-bearer for military specification

metal scrapers/wipers. Gadjets is a qualified military suppler (QPL 5049D)

with an assigned QAR, on-site inspection and packaging facilities and

conformance with all required standards for manufacture, quality and

inspection. The Hydrowype MS28776-M2 wiper family is the only product family

offering all MS28776-M2 material offerings including Brasses, Bronzes and

Copper-Beryllium, and all styles, I, II and III. Each MS26776-M2 part is

inspected and certified to meet all rod-RCpressure, breakout friction, gap

tolerance and light tightness stipulations set forth in the Mil-spec. Gadjets

is the patent holder for the two-piece 74B410064-103 MS28776-M2 variants and

is sole-source supplier for the military 4G13763-101A heavy aircraft landing

gear variants of MS28776-M2 parts. Unless otherwise stipulated, we will offer

a Style-1 AH line wiper (without spring) when MS28776 is requested. However

wherever possible we recommend use of superior Style II and Style III, fully

MS28776-M2 (A-Series) compliant wipers. |

| |

|

|

| |

|

|

|

|

|

|

|

|

|

|

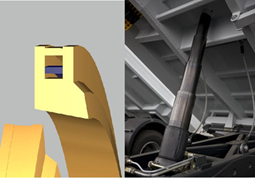

AN-Style

Heavy-Duty Commercial Grade Metal Wiper - (A-Series) |

|

|

|

The AB

line of metal wipers is identical to the full MS28776-M2 series of wipers in

all respects except that they are not plated with the government-stipulated

Cadmium, therefore comply with regulations restricting the use of Cadmium and

certain Chromates. As such, this product line offers greater economy, safety

and is interchangeable with MS28776-M2 wipers. Alternative plating and

Chromate options are also available, including Nickle. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

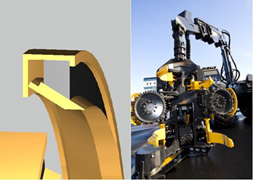

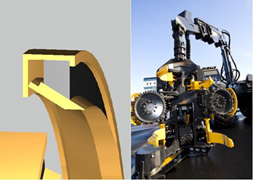

M-Style

Medium-Duty, Fine Particle (M-Series) Metal/Polymer Wipers |

|

|

|

|

|

|

|

|

|

|

|

Hydrowype

M-Series wipers are intended for use in medium-duty (relatively light in the

context of metal wiper) applications where a light-weight, flexible wiper

design will suffice and where gland space is ample. This is a relatively wide

and deep profile which incorporates an elastomeric seal to ensure

contaminants cannot bypass the wiper around the clearance between the wiper

OD and the groove in the gland. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

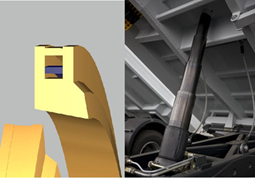

D-Style

Ultra-Heavy-Duty (D-Series) Metal Wipers |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The

D-Series wiper line including the Style-DS and accompanying Style-DP

elastomeric wiper, is intended for use primarily where the following

conditions are to be encountered: direct contact of the wiper with

ultra-heated or molten materials; severely adhered contaminants (baked into

or fused with the rod surface); significant shock loading and side-loadings;

and existing rod damage, where a tool-steel grade wiper is required to scrape

off deflected (dislodged) rod material. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Two-piece Rod

Wipers (Style-AC, Style-AG and Style-DC) |

|

|

|

|

|

|

|

|

|

|

|

Hydrowype

two-piece wipers have a wiper body that is fully broken into two halves to

permit live replacement where full tear down and removal of the rod-end,

clevis or linkage is not desirable. A proprietary spring is used to retain

the two halves as a single working element upon installation so as to be

ideal for use where the wiper is likely to encounter accelerated wear,

typically from super abrasive materials or the presence of significant side

load. This wiper is ideal in field maintenance-repair situations and an

installation tool is available to aid in installing the spring even under the

most difficult break down or maintenance conditions. The two-piece wiper is

especially effective when combined with the Hydrowype Adapter or some similar

means of fixing the ring in place outboard of the cylinder cap and existing

packing. Thus, in retrofit situations, the adapter can simply be released

from the end-cap, the spring and two halves of ring removed, and replaced

with a new wiper. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Installation

Adapters (AD-series) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

For all

A-Series (MS28776-M2 or AN) interchangeable wipers, the Hydrowype Adapter kit

is available comprising a keeper plate and follower plate pair, to secure the

wiper outboard of the cylinder end-cap or gland. These adapters are provided

in plated or coated sheet formed metal, complete with the necessary profile

to effectively retain the wiper. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|